What is a Ladle Pre-Heating System?

A Ladle Pre-Heating System is an essential industrial solution used to heat ladles before they receive molten metal. Pre-heating removes moisture and ensures thermal stability, preventing thermal shock, minimizing metal temperature drop, and improving casting quality.

Our Ladle Pre-Heating Systems in Bangalore and Shivamogga are available in vertical and horizontal burner configurations and can be operated using gas, oil, or electricity for efficient performance.

Key Features of DK Thermal Tech Ladle Pre-Heating Systems

Key Features:At DK Thermal Tech, our ladle preheaters are engineered for safety, reliability, and energy efficiency in foundries and metal casting environments.

Standard Features Include:These systems are designed to reach temperatures up to 1000°C quickly and uniformly to prepare ladles for immediate molten metal transfer.

Applications of Ladle Pre-Heating Systems in Bangalore and Shivamogga

Our Ladle Pre-Heating Systems are widely used in the following sectors:

- Steel Plants

- Iron Foundries

- Aluminum and Non-Ferrous Metal Casting Units

- Investment Casting and Precision Casting Units

- Re-Rolling Mills

- Furnace Integrated Melting and Pouring Lines

In these industries, preheating ensures thermal integrity, lowers energy losses, and reduces casting defects.

Choose the Right Ladle Preheating System

Vertical Ladle Preheaters

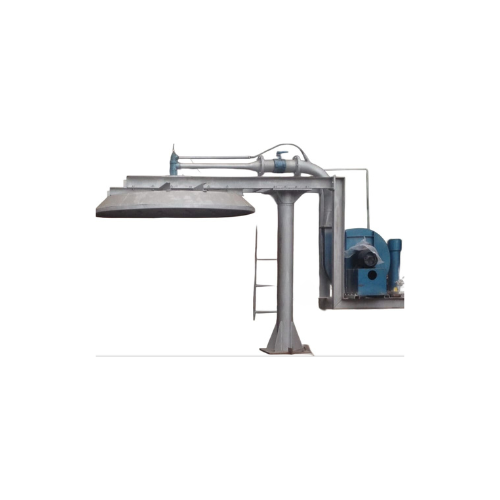

Swing-Type Ladle Preheaters

- Movable heating head

- Better flexibility for different ladle positions

- Suitable for integrated casting lines

Trolley-Mounted Systems

- Portable design for multiple ladles

- Improves workflow and space utilization

- Best for medium-size foundries

We help you select the most efficient model based on your ladle capacity, operation mode, and casting workflow.

Why Choose DK Thermal Tech in Bangalore and Shivamogga?

Tailored Systems

All units are custom-designed to match your ladle size, fuel type, and casting schedule.

Reliable Support

Local service teams ensure quick installation, troubleshooting, and AMCs in Karnataka.

Trusted by Foundries

Our systems are installed in top-tier foundries and steel plants, known for their consistent performance.

Cost-Effective Solutions

Fuel-efficient burner technology and high insulation reduce operational costs while ensuring safety and output quality.