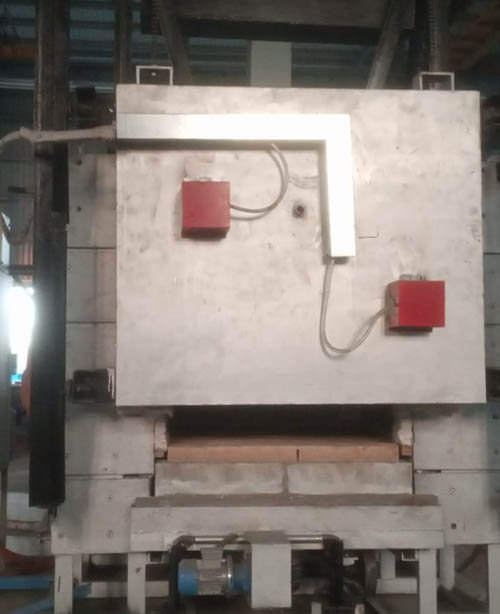

Normalizing Furnace

We are the leading manufacturer and exporter of Normalizing Furnace from Sangli, Maharashtra.

Normalising involves heating a material to an elevated temperature and then allowing it to cool back to room temperature by exposing it to room temperature air after it is heated.

This heating and slow cooling alters the microstructure of the metal which in turn reduces its hardness and increases its ductility.

What is a Normalizing Furnace?

A Normalizing Furnace is an industrial heat treatment system used to heat ferrous metals to a specific temperature above their transformation range, followed by air cooling. This process helps refine grain structure, improve mechanical properties, and relieve internal stresses in materials.

Our Normalizing Furnace in Bangalore can be integrated with bogie hearth, pit type, or box furnace designs to accommodate various part sizes, geometries, and heat treatment volumes.

Key Features of DK Thermal Tech Normalizing Furnaces

Key Features:Each DK Thermal Tech Normalizing Furnace is designed to deliver uniform heating, controlled atmosphere (if required), and repeatable process results for steel and cast iron components.

Standard Features Include:Our furnaces ensure precise normalizing for castings, forgings, and fabricated parts, reducing post-treatment defects and improving performance.

Applications of Normalizing Furnaces in Bangalore and Shivamogga

Our Normalizing Furnaces are widely used across several key industrial sectors, including:

- Steel Casting and Forging Plants

- Automobile and Tractor Component Manufacturing

- Fabricated Structure Stress Relief

- Tool and Die Processing

- Railway and Defense Component Treatment

- Foundries and Heat Treatment Facilities

DK Thermal Tech supports heavy engineering and machining industries in Karnataka with reliable, high-throughput normalizing solutions.

Choose the Right Normalizing Setup

Box Type Normalizing Furnaces

Bogie Hearth Normalizing Furnaces

- Handles large, heavy, or bulky components

- Motorized trolley for smooth loading/unloading

- Excellent temperature uniformity

Pit Type Normalizing Furnaces

- Vertical loading for long shafts, rods, and pipes

- Space-saving design

- Consistent and even heating across length

We help you select the optimal normalizing furnace configuration based on your production needs and part specifications.

Why Choose DK Thermal Tech in Bangalore and Shivamogga?

Tailored Engineering

We custom-build every furnace to match your part size, material type, and throughput goals.

Local Support Network

With teams based in Bangalore and Shivamogga, we provide quick service, installation, and technical support.

Field-Proven Solutions

Our furnaces are trusted by foundries, auto manufacturers, and tool makers for precise and consistent heat treatment.

Efficiency and Value

With high thermal efficiency and robust construction, our systems offer long-term value through reduced downtime and better product quality.